Learn more about Elevator World, the top trade magazine for the Elevator Industry.

Read the article on ElevatorWorld.com.

Check out our blog post on this exciting project.

(Note – Article text copy is also provided below page images for easier reading on certain devices)

KSA EXPO 2020 PAVILION

Inclined Lifts

Dubai, U.A.E.

submitted by Hill Hiker, Inc.

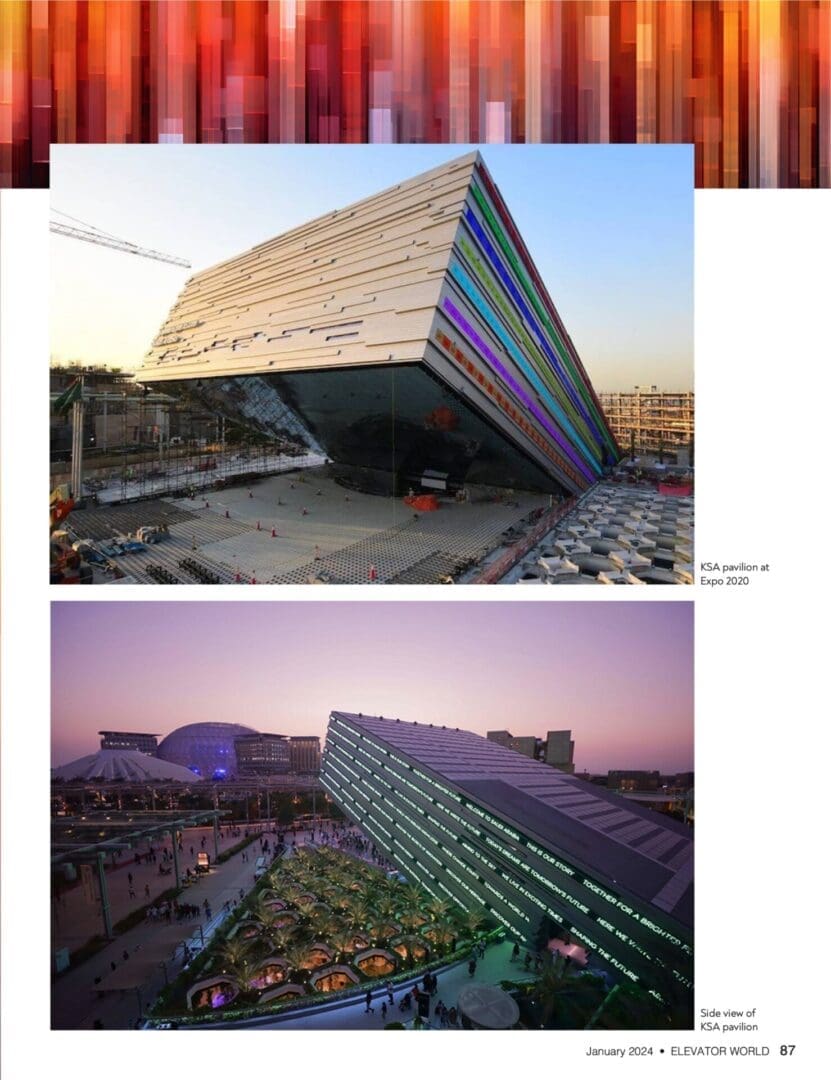

In 2018, the Kingdom of Saudi Arabia (KSA) began the design of the KSA Pavilion, scheduled to be built for Expo 2020, a type of World’s Fair held every five years since 1851. Expo 2020 in Dubai, U.A.E, was the first World Expo hosted in the Middle East, Africa or South Asia. The theme of the Expo was “Connecting Minds, Creating the Future.” Countries from around the world sought to build pavilions or smaller buildings that would showcase their culture, history and innovation. Considering the location and the mission of Expo 2020, the leaders of the KSA wanted to showcase the beauty of their land, culture and history while also highlighting their vision of the future.

Boris Micka Associates (BMA) designed a building for the KSA that resembled a window opening from the ground, rising six stories at a 24° angle. To create the window design, the whole building was cantilevered. Traditional vertical elevators would not work in this space. BMA contacted Dar Al-Handasah Consultants (DAR) to resolve the issue. The consulting group naturally included two escalators, one to bring visitors up to the top floor and one to bring them back down. Still, escalators would preclude disabled visitors or visitors with children in strollers. In January 2019, DAR turned to Hill Hiker, Inc., because the only solution was two custom inclined elevators that would run parallel to the escalators. Hill Hiker was the ideal supplier for the inclined elevators, though there were several challenges to work through.

Overcoming Challenges

The client, Saudi Aramco, contracted with Khatib & Alami for project management and to be Architect of Record. Khatib & Alami chose ALEC Engineering & Contracting as the main contractor. ALEC then subcontracted TK Elevator (TKE) Dubai to provide and install the conveyance equipment for the project, including all the elevators and escalators. DAR and ALEC connected TKE to Hill Hiker to provide the inclined elevators. Hill Hiker had been specified in the contract documents, but the design and drawings were not complete and continued during construction of the building, which began in February 2019. As with many elevator and escalator installations, space was minimal. Although the pavilion boasted an overall size of 140,566 ft2 (13,056 m2), only two 5 ft 7 in. (1.7-m) corridors were available for the inclined elevators. The width was the same, but the distance of travel was not. The first elevator was to be 125-ft long, with the second being 92.5-ft long. Hill Hiker involved VAA, a structural engineering firm out of Plymouth, Minnesota, to help overcome the space restrictions.

Given the overall cantilever design of the building, the contractors included two sets of W21 X 101 I-beams as the support system for the elevators. VAA used Hill Hiker’s signature extra-large commercial 4-ft-wide captured rail system. The team designed the first and last cross members of each track section to make .5-in. through-bolt connections to the provided I-beams by field-drilled holes.

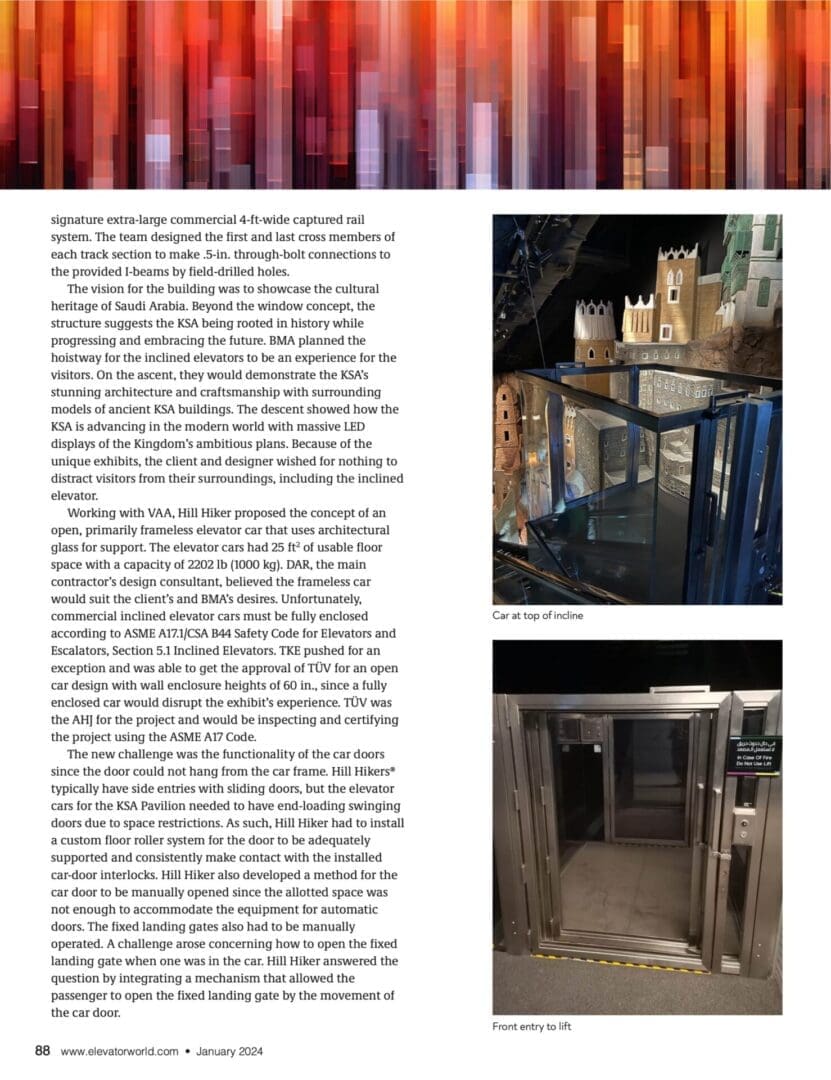

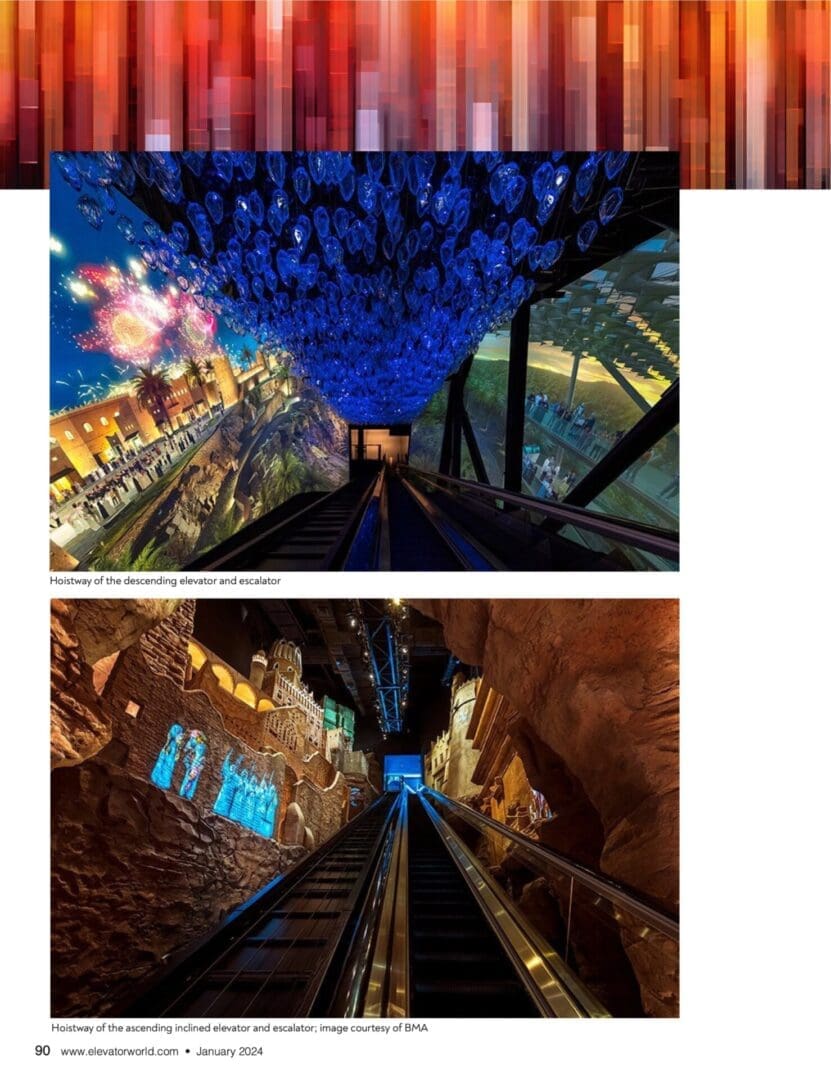

The vision for the building was to showcase the cultural heritage of Saudi Arabia. Beyond the window concept, the structure suggests the KSA being rooted in history while progressing and embracing the future. BMA planned the hoistway for the inclined elevators to be an experience for the visitors. On the ascent, they would demonstrate the KSA’s stunning architecture and craftsmanship with surrounding models of ancient KSA buildings. The descent showed how the KSA is advancing in the modern world with massive LED displays of the Kingdom’s ambitious plans. Because of the unique exhibits, the client and designer wished for nothing to distract visitors from their surroundings, including the inclined elevator.

Working with VAA, Hill Hiker proposed the concept of an open, primarily frameless elevator car that uses architectural glass for support. The elevator cars had 25 ft2 of usable floor space with a capacity of 2202 lb (1000 kg). DAR, the main contractor’s design consultant, believed the frameless car would suit the client’s and BMA’s desires. Unfortunately, commercial inclined elevator cars must be fully enclosed according to ASME A17.1/CSA B44 Safety Code for Elevators and Escalators, Section 5.1 Inclined Elevators. TKE pushed for an exception and was able to get the approval of TÜV for an open car design with wall enclosure heights of 60 in., since a fully enclosed car would disrupt the exhibit’s experience. TÜV was the AHJ for the project and would be inspecting and certifying the project using the ASME A17 Code.

The new challenge was the functionality of the car doors since the door could not hang from the car frame. Hill Hikers® typically have side entries with sliding doors, but the elevator cars for the KSA Pavilion needed to have end-loading swinging doors due to space restrictions. As such, Hill Hiker had to install a custom floor roller system for the door to be adequately supported and consistently make contact with the installed car-door interlocks. Hill Hiker also developed a method for the car door to be manually opened since the allotted space was not enough to accommodate the equipment for automatic doors. The fixed landing gates also had to be manually operated. A challenge arose concerning how to open the fixe landing gate when one was in the car. Hill Hiker answered the question by integrating a mechanism that allowed the passenger to open the fixed landing gate by the movement of the car door.

Creative, Custom Solutions

With the car design set, Hill Hiker had to decide which drive system would best suit the project. Typically, inclined elevators are traction machines, counterbalanced systems or winding drum machines. The ended loading doors automatically excluded traction machines because of the necessary bottom return pully. Hill Hiker also ruled out a counterbalance system since the elevator rail would have a much higher profile to accommodate the counterbalance rail. With only one option available, Hill Hiker had to manufacture a winding drum machine that could fit in a confined space since the building could not house a suitably sized motor room. The building allowed only 4 ft 7 in. of head space in the motor room, which is the definition of a confined space. Hill Hiker had to ensure all proper safety precaution signage was posted and machine guarding installed. The drive system was a 20-hp brake motor connected to a double reduction worm-to-worm gearbox. Hill Hiker used two .5-in. diameter steel 8 X 19 elevator ropes on a 22 in. in diameter by 24-in.-wide grooved drum. Each rope had a 14,500 lb minimum breaking strength.

In the industry of inclined elevators, traveling cables always pose a problem. Hill Hiker usually uses wireless technology for residential projects, but the ASME A17.1/CSA B44 Code requires hardwired controls and in-car communication for commercial applications. Hill Hiker prefers an energy chain setup mounted to the side of the track/rails, but the recurring theme of lack of space for the elevator forced Hill Hiker to consider a new option. We decided to use reels: One for the traveling cable and one for the in-car communication wires. Though not as reliable, safe and durable as a wireless system, Hill Hiker made the reels functional and stocked them with cable retention and slack rope devices. Hill Hiker designed a custom track roller to prevent the elevator rope from rubbing on the rail and helped lessen the friction of the traveling cable, allowing the reel to retract more easily.

The chassis for the elevator car was also custom. Because of the limited space in the motor room, Hill Hiker chose to use its proprietary overspeed governor that travels with the chassis. The chassis had three independent style A safeties for each of the Hill Hiker® cars traveling at 98 ft/min (0.5 m/s).

Once the design and manufacturing challenges were addressed, it was time for installation, but the challenges were not over yet. The KSA Pavilion and EXPO 2020 were supposed to open on October 1, 2020. Hill Hiker’s team was in Dubai working on Phase II of the installation in March 2020 when the COVID-19 global pandemic upended the world and the EXPO. The Hill Hiker installation team barely made it out of Dubai, getting the last four seats on one of the very last flights out. The pandemic caused enormous delays in the project for everyone.

Hill Hiker, working with and through TKE, completed its work on the inclined elevators in August 2021. Some portions of the equipment were installed over phone or video communications. As called for in the project specifications, the AHJ in Dubai, U.A.E., granted special permission for the inclined elevators to be inspected under the North American ASME A17.1/ CSA B44 Code. TÜV inspected both inclined elevators. In response to an interview for the present article, Hill Hiker Head of Marketing Duncan MacLachlan stated, “No other Hill Hiker has ever gone through such a thorough inspection.”

Summary

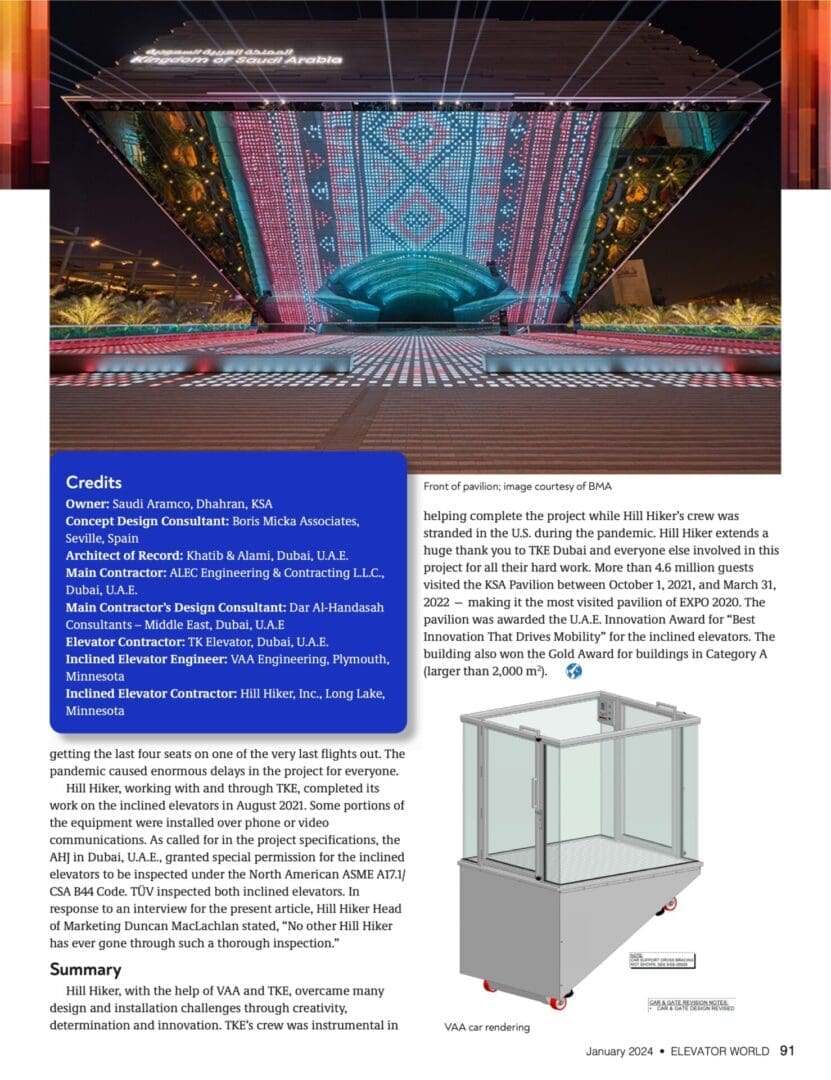

Hill Hiker, with the help of VAA and TKE, overcame many design and installation challenges through creativity, determination and innovation. TKE’s crew was instrumental in helping complete the project while Hill Hiker’s crew was stranded in the U.S. during the pandemic. Hill Hiker extends a huge thank you to TKE Dubai and everyone else involved in this project for all their hard work. More than 4.6 million guests visited the KSA Pavilion between October 1, 2021, and March 31, 2022 — making it the most visited pavilion of EXPO 2020. The pavilion was awarded the U.A.E. Innovation Award for “Best Innovation That Drives Mobility” for the inclined elevators. The building also won the Gold Award for buildings in Category A (larger than 2,000 m2).

Credits

- Owner: Saudi Aramco, Dhahran, KSA

- Concept Design Consultant: Boris Micka Associates, Seville, Spain

- Architect of Record: Khatib & Alami, Dubai, U.A.E.

- Main Contractor: ALEC Engineering & Contracting L.L.C., Dubai, U.A.E.

- Main Contractor’s Design Consultant: Dar Al-Handasah Consultants – Middle East, Dubai, U.A.E

- Elevator Contractor: TK Elevator, Dubai, U.A.E.

- Inclined Elevator Engineer: VAA Engineering, Plymouth, Minnesota

- Inclined Elevator Contractor: Hill Hiker, Inc., Long Lake, Minnesota

- Photos: Boris Micka Associates, TK Elevator & Hill Hiker, Inc.

Source:

Hill Hiker, Inc. “KSA EXPO 2020 PAVILION.” Elevator World, Jan. 2024, pp. 86-91.