Learn more about the Observatorio 1873 located in Mazatlan, Mexico.

Learn more about Elevator World, the top trade magazine for the Elevator Industry.

(Note – Article text copy is also provided below page images for easier reading on certain devices)

More Project Info

Parque Turistico Observatorio 1873

Mazatlán, Mexico

submitted by Bill MacLachlan, Hill Hiker, Inc.

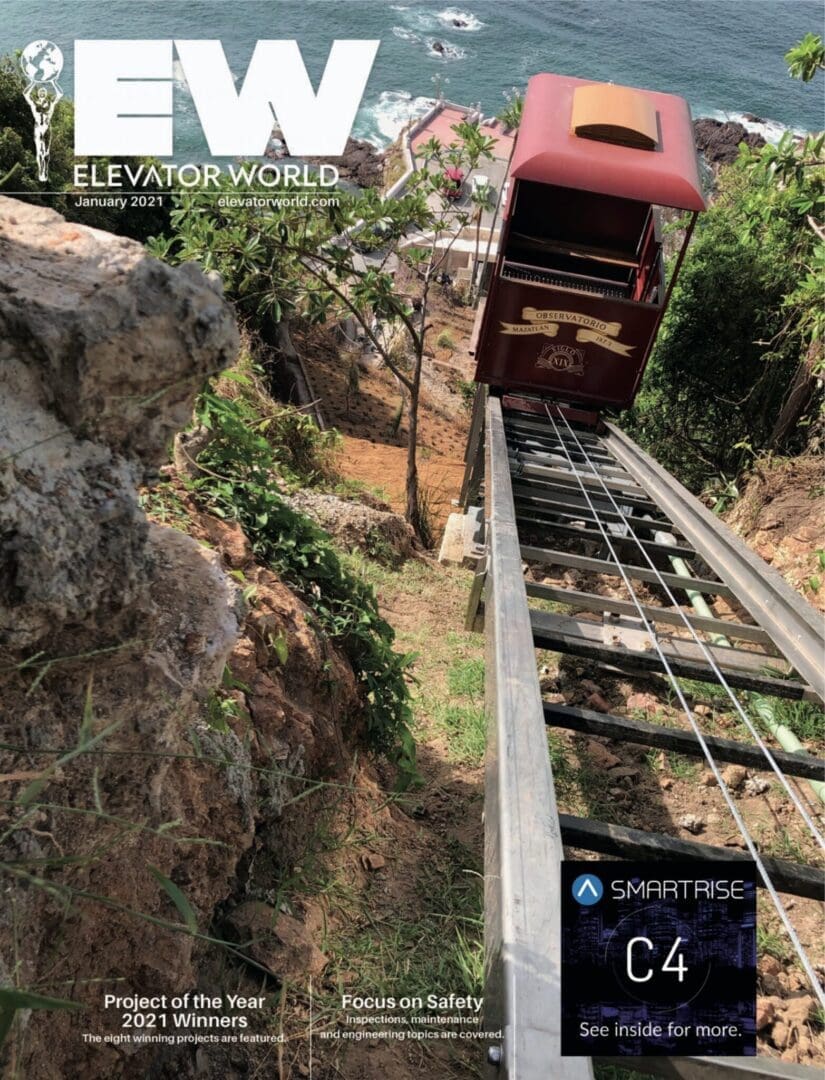

Amado Guzman, an entrepreneur and businessman in Mazatlán, Mexico, had a vision to restore the city’s historic and once-beautiful observatory. The people of Mazatlán originally built it as a military outpost atop Cerro del Vigia to protect people from invasions of enemy ships and pirates. In 1873, the need and strategic advantage of the outpost waned, so the local government agreed to transition the building from military to scientific use. The outpost became the second meteorological and seismological observatory in the country.

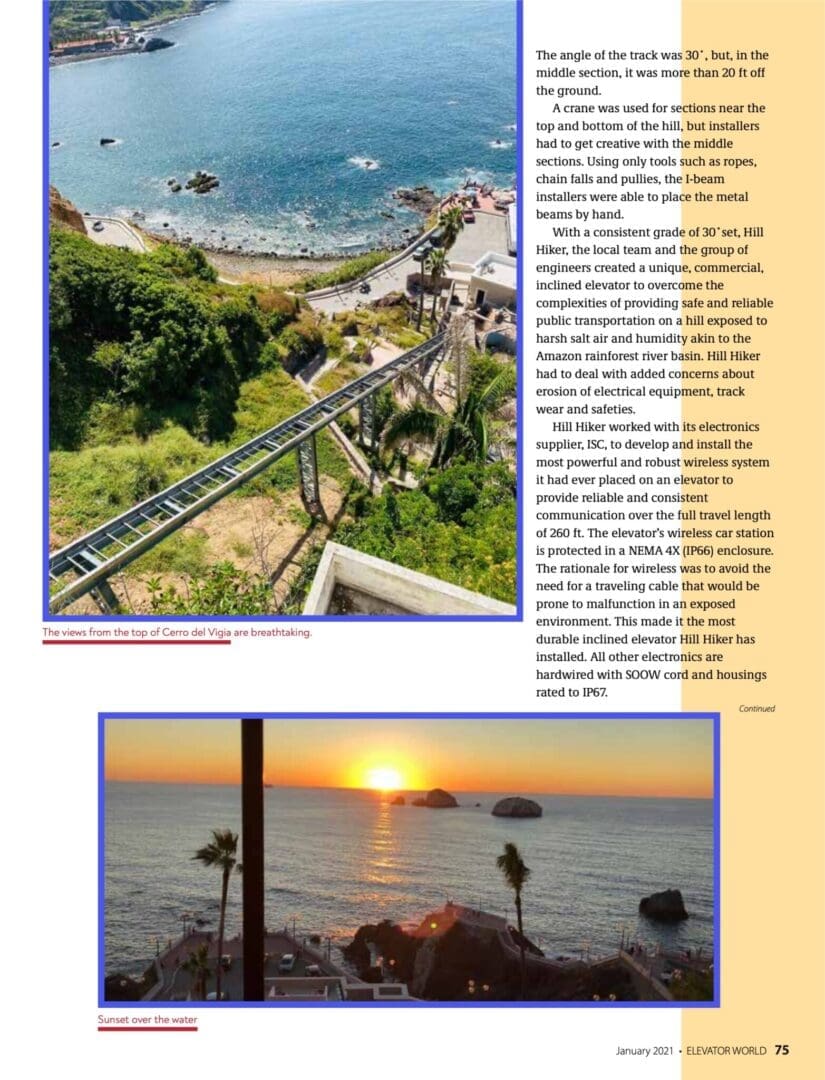

Guzman believes everyone should experience the history of the building and the unique views it offers. Perched on the highest bluff in the city, 289 ft above sea level, the observatory was difficult to access, although the nearly perfect vista was worth any difficulty. When Guzman contacted Hill Hiker, Inc. to take on the task, the Minnesota-based company was ready, as it had been installing inclined elevators in challenging locations throughout the U.S. and world since it was founded in 1997.

Before any work could start, Hill Hiker owner and President Bill MacLachlan flew from Minneapolis to Mazatlán to explore the feasibility of an inclined elevator. Machete in hand, MacLachlan and the local team trudged through decades of overgrowth to chart a path for the elevator. Hill Hiker then connected the local team with its engineers at VAA, LLC. Through six months of engineering, manufacturing, hill preparation and even some trepidation, Hill Hiker was ready to install the inclined elevator.

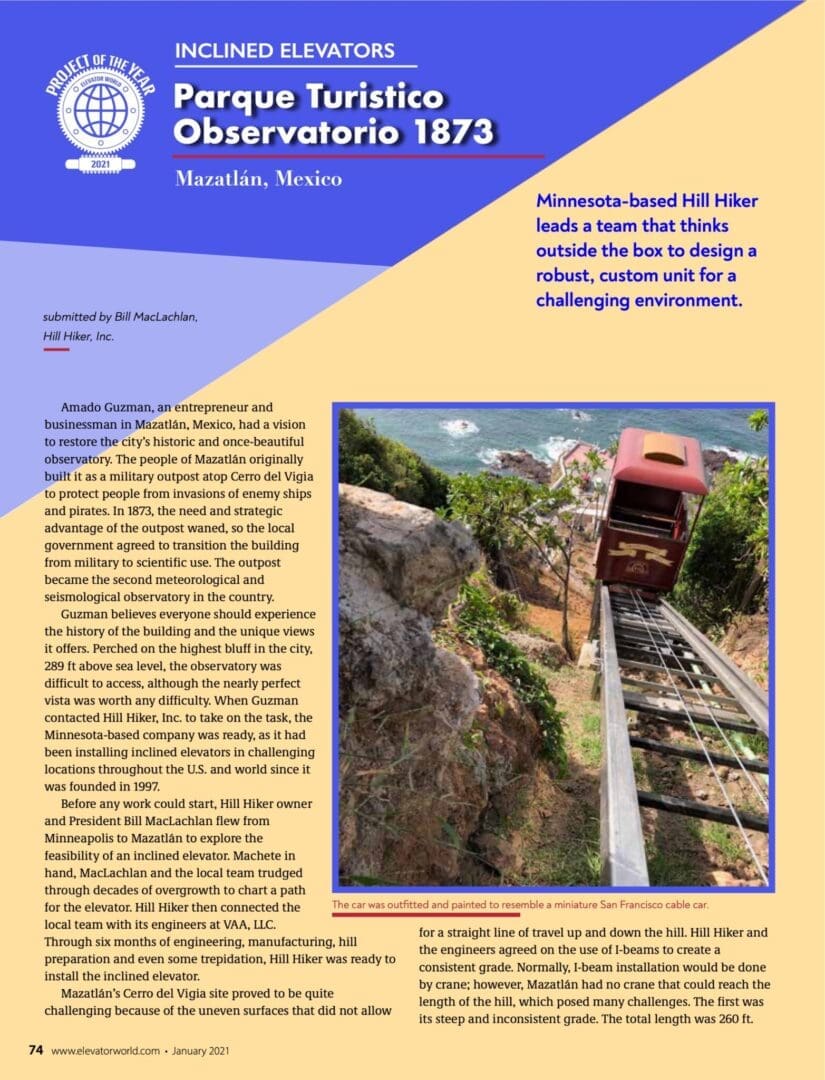

Mazatlán’s Cerro del Vigia site proved to be quite challenging because of the uneven surfaces that did not allow for a straight line of travel up and down the hill. Hill Hiker and the engineers agreed on the use of I-beams to create a consistent grade. Normally, I-beam installation would be done by crane; however, Mazatlán had no crane that could reach the length of the hill, which posed many challenges. The first was its steep and inconsistent grade. The total length was 260 ft. The angle of the track was 30˚, but, in the middle section, it was more than 20 ft off the ground.

A crane was used for sections near the top and bottom of the hill, but installers had to get creative with the middle sections. Using only tools such as ropes, chain falls and pullies, the I-beam installers were able to place the metal beams by hand.

With a consistent grade of 30˚set, Hill Hiker, the local team and the group of engineers created a unique, commercial, inclined elevator to overcome the complexities of providing safe and reliable public transportation on a hill exposed to harsh salt air and humidity akin to the Amazon rainforest river basin. Hill Hiker had to deal with added concerns about erosion of electrical equipment, track wear and safeties.

Hill Hiker worked with its electronics supplier, ISC, to develop and install the most powerful and robust wireless system it had ever placed on an elevator to provide reliable and consistent communication over the full travel length of 260 ft. The elevator’s wireless car station is protected in a NEMA 4X (IP66) enclosure. The rationale for wireless was to avoid the need for a traveling cable that would be prone to malfunction in an exposed environment. This made it the most durable inclined elevator Hill Hiker has installed. All other electronics are hardwired with SOOW cord and housings rated to IP67.

Additional System Features

Gearbox ratio and type: 150:1, worm/worm double reduction

Brake: AC Electro Magnetic No. of ropes: Two

Rated breaking strength: 14,400 lb per rope

Rope material and diameter: Galvanized aircraft cable, 7 X 19-3/8-in.

Machinery workspace type: Fully enclosed room; disconnect in sight of motor and within reach of panel

Outside width of car: 70-7/8 in.

Outside length of car: 99-1/8 in.

Platform material: Marine-grade, Americans With Disabilities Act-compliant, nonslip fiber-grate flooring

Motor: UL-certified variable-frequency drive AC motor with soft start and soft slowdown

Call stations: Onboard and at each landing station with security

Emergency-stop buttons: Top, bottom and onboard

Track system: Captured rail design Overspeed governor and spring buffer location: On car

Security: Keyed or keyless code

Limit switches: Deceleration, directional and terminal switches at top and bottom of hill

Electrical safety features: Disconnect with lockout/tagout, low-voltage switches and controls

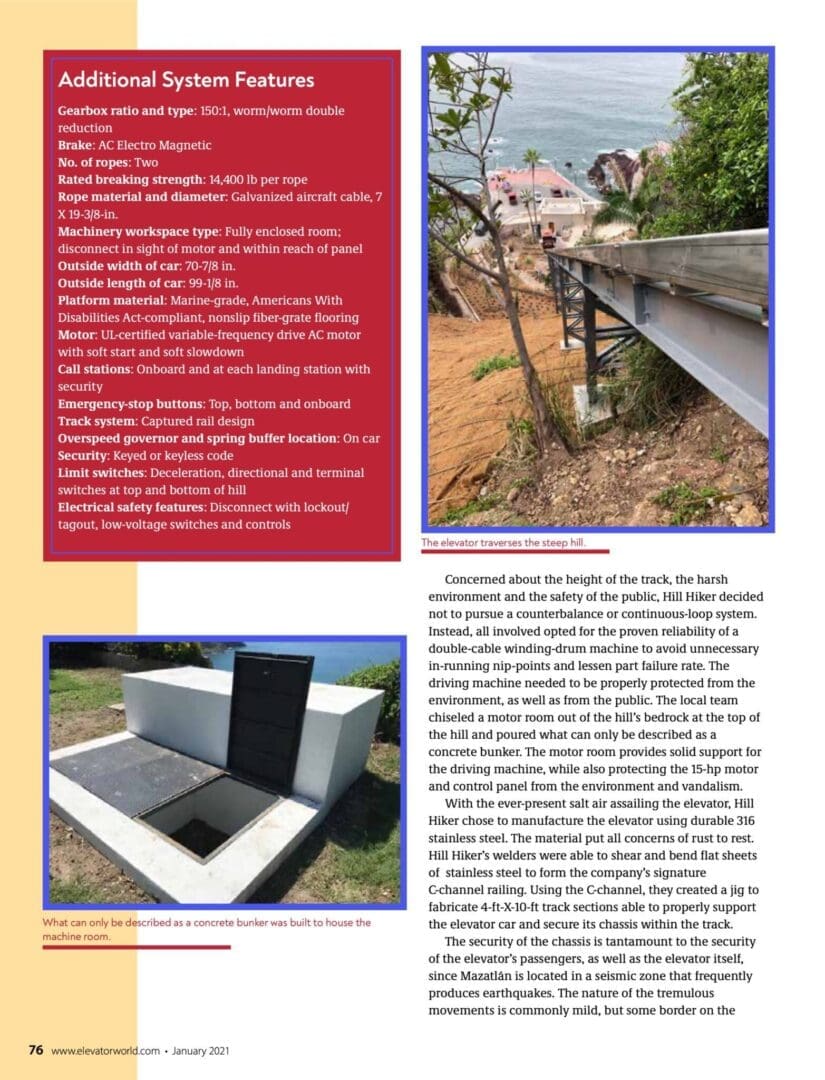

Concerned about the height of the track, the harsh environment and the safety of the public, Hill Hiker decided not to pursue a counterbalance or continuous-loop system. Instead, all involved opted for the proven reliability of a double-cable winding-drum machine to avoid unnecessary in-running nip-points and lessen part failure rate. The driving machine needed to be properly protected from the environment, as well as from the public. The local team chiseled a motor room out of the hill’s bedrock at the top of the hill and poured what can only be described as a concrete bunker. The motor room provides solid support for the driving machine, while also protecting the 15-hp motor and control panel from the environment and vandalism.

With the ever-present salt air assailing the elevator, Hill Hiker chose to manufacture the elevator using durable 316 stainless steel. The material put all concerns of rust to rest. Hill Hiker’s welders were able to shear and bend flat sheets of stainless steel to form the company’s signature C-channel railing. Using the C-channel, they created a jig to fabricate 4-ft-X-10-ft track sections able to properly support the elevator car and secure its chassis within the track.

The security of the chassis is tantamount to the security of the elevator’s passengers, as well as the elevator itself, since Mazatlán is located in a seismic zone that frequently produces earthquakes. The nature of the tremulous movements is commonly mild, but some border on the extreme. Considering the supports for the I-beam and strength of the track’s design, Hill Hiker, the local team and the engineers are confident the elevator can handle most natural phenomenons.

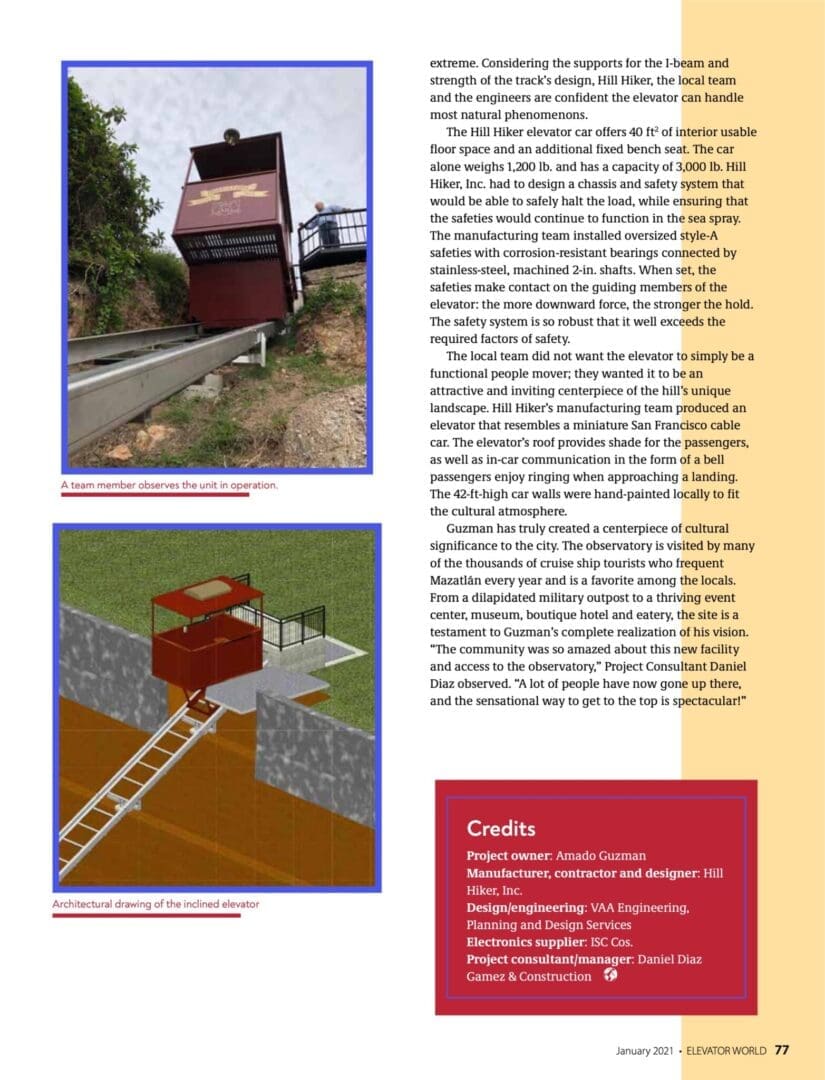

The Hill Hiker elevator car offers 40 ft2 of interior usable floor space and an additional fixed bench seat. The car alone weighs 1,200 lb. and has a capacity of 3,000 lb. Hill Hiker, Inc. had to design a chassis and safety system that would be able to safely halt the load, while ensuring that the safeties would continue to function in the sea spray. The manufacturing team installed oversized style-A safeties with corrosion-resistant bearings connected by stainless-steel, machined 2-in. shafts. When set, the safeties make contact on the guiding members of the elevator: the more downward force, the stronger the hold. The safety system is so robust that it well exceeds the required factors of safety.

The local team did not want the elevator to simply be a functional people mover; they wanted it to be an attractive and inviting centerpiece of the hill’s unique landscape. Hill Hiker’s manufacturing team produced an elevator that resembles a miniature San Francisco cable car. The elevator’s roof provides shade for the passengers, as well as in-car communication in the form of a bell passengers enjoy ringing when approaching a landing. The 42-ft-high car walls were hand-painted locally to fit the cultural atmosphere.

Guzman has truly created a centerpiece of cultural significance to the city. The observatory is visited by many of the thousands of cruise ship tourists who frequent Mazatlán every year and is a favorite among the locals. From a dilapidated military outpost to a thriving event center, museum, boutique hotel and eatery, the site is a testament to Guzman’s complete realization of his vision. “The community was so amazed about this new facility and access to the observatory,” Project Consultant Daniel Diaz observed. “A lot of people have now gone up there, and the sensational way to get to the top is spectacular!”

Credits

Project owner: Amado Guzman

Manufacturer, contractor and designer: Hill Hiker, Inc.

Design/engineering: VAA Engineering,

Planning and Design Services

Electronics supplier: ISC Cos.

Project consultant/manager: Daniel Diaz Gamez & Construction

Source:

MacLachlan, Bill. “Parque Turistico Observatorio 1873.” Elevator World, Jan. 2021, pp. 74-77.