Learn more about Elevator World, the top trade magazine for the Elevator Industry.

Read the article on ElevatorWorld.com.

Check out our blog post on this exciting project.

(Note – Article text copy is also provided below page images for easier reading on certain devices)

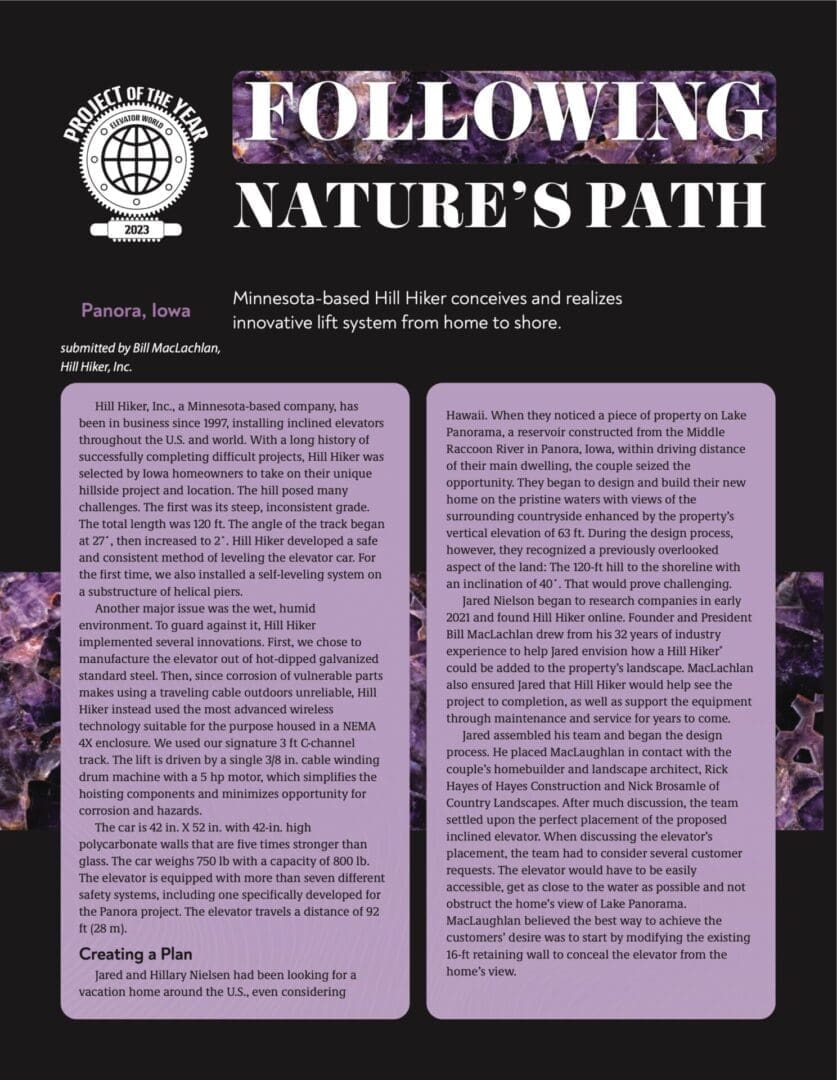

FOLLOWING NATURE’S PATH

Panora, Iowa

Minnesota-based Hill Hiker conceives and realizes innovative lift system from home to shore.

submitted by Bill MacLachlan, Hill Hiker, Inc.

Hill Hiker, Inc., a Minnesota-based company, has been in business since 1997, installing inclined elevators throughout the U.S. and world. With a long history of successfully completing difficult projects, Hill Hiker was selected by Iowa homeowners to take on their unique hillside project and location. The hill posed many challenges. The first was its steep, inconsistent grade. The total length was 120 ft. The angle of the track began at 27˚, then increased to 2˚. Hill Hiker developed a safe and consistent method of leveling the elevator car. For the first time, we also installed a self-leveling system on a substructure of helical piers. Another major issue was the wet, humid environment. To guard against it, Hill Hiker implemented several innovations. First, we chose to manufacture the elevator out of hot-dipped galvanized standard steel. Then, since corrosion of vulnerable parts makes using a traveling cable outdoors unreliable, Hill Hiker instead used the most advanced wireless technology suitable for the purpose housed in a NEMA 4X enclosure. We used our signature 3 ft C-channel track. The lift is driven by a single 3/8 in. cable winding drum machine with a 5 hp motor, which simplifies the hoisting components and minimizes opportunity for corrosion and hazards. The car is 42 in. X 52 in. with 42-in. high polycarbonate walls that are five times stronger than glass. The car weighs 750 lb with a capacity of 800 lb. The elevator is equipped with more than seven different safety systems, including one specifically developed for the Panora project. The elevator travels a distance of 92 ft (28 m).

Creating a Plan

Jared and Hillary Nielsen had been looking for a vacation home around the U.S., even considering Hawaii. When they noticed a piece of property on Lake Panorama, a reservoir constructed from the Middle Raccoon River in Panora, Iowa, within driving distance of their main dwelling, the couple seized the opportunity. They began to design and build their new home on the pristine waters with views of the surrounding countryside enhanced by the property’s vertical elevation of 63 ft. During the design process, however, they recognized a previously overlooked aspect of the land: The 120-ft hill to the shoreline with an inclination of 40˚. That would prove challenging. Jared Nielson began to research companies in early 2021 and found Hill Hiker online. Founder and President Bill MacLachlan drew from his 32 years of industry experience to help Jared envision how a Hill Hiker® could be added to the property’s landscape. MacLachlan also ensured Jared that Hill Hiker would help see the project to completion, as well as support the equipment through maintenance and service for years to come. Jared assembled his team and began the design process. He placed MacLaughlan in contact with the couple’s homebuilder and landscape architect, Rick Hayes of Hayes Construction and Nick Brosamle of Country Landscapes. After much discussion, the team settled upon the perfect placement of the proposed inclined elevator. When discussing the elevator’s placement, the team had to consider several customer requests. The elevator would have to be easily accessible, get as close to the water as possible and not obstruct the home’s view of Lake Panorama. MacLachlan believed the best way to achieve the customers’ desire was to start by modifying the existing 16-ft retaining wall to conceal the elevator from the home’s view. Feasibility assured, an on-site meeting was scheduled with all concerned parties. Harrison Swadley, Hill Hiker sales assistant, met with the homeowners, builder and landscape team. He spent time establishing a string line to represent the path of the elevator. The string revealed that the hill’s angle was

not consistent. The string started at the top of the hill with 27˚ of inclination and became much steeper at the bottom, changing to 42˚. Hill Hiker has installed elevators steeper than 70˚, so the company could overcome either angle. However, we had to determine the best way to keep the elevator car level

through the curve as it traveled downhill.

Complications Multiply

To further complicate matters, the ground and hill did not allow the use of concrete, which Hill Hiker typically utilizes for the support structure. Generally, commonly installed elevator substructures are either 18-in. round columns with wet-set, all-thread or 2-ft X 5-ft concrete pads with support posts hammer-drilled in place. However, neither option would work well, given the hillside’s limited accessibility, soil conditions and differing extreme angles. Taking into consideration the hill’s difficulty, Swadley offered the possibility of using helical piers (or screw piles) as the support structure. Country Landscape, being familiar with helical piles, felt comfortable with the method and finalized the design. Helical piers are typically used in terrain where the soil is mainly sand. The piers minimally disturb the soil and help retain the hillside. During installation, the team used compact utility loaders with a telescoping auger attachment. The attachment is equipped with a gauge to indicate when the pier meets the engineering requirements. Since the piers are rounded, Hill Hiker used a custom bracketing system involving U-bolts, plates and attachment tubes. We further secured the piers by cross bracing and tying the piers together. With the new information, exact measurements and pictures of the string line, Swadley and MacLachlan began to strategize. They saw the need for a self-leveling system. Since the substructure was required to be helical piles, MacLachlan decided to pursue an electrical leveling system instead of a mechanically based system — the first Hill Hiker® installed on helical piers with a leveling system. An automatic or electrical self-leveling Hill Hiker® pivots the elevator car on the uphill side of the chassis. The downhill side of the elevator car is made level through the use of a screw-driven actuator. Mounted under the car’s platform, a level sensor identifies any out-oflevel condition. When detecting that the car is out-of-level, the sensor sends an output signal that activates a contactor attached to the actuator, leveling the car. To provide the best ride experience and meet the load requirements, Hill Hiker developed a new feature. Through the wireless control system, we slowed the rated speed of travel from 60 ft/min to 40 ft/min by way of a wireless signal. The transmitter for the signal transmits whenever the actuator is activated. The slower speed allows the actuator to properly adjust the 750 lb car with an 800 lb live-load capacity without impacting ride quality or smoothness. The screw actuator has a capacity of 2000 lb and a stroke of 24 in.

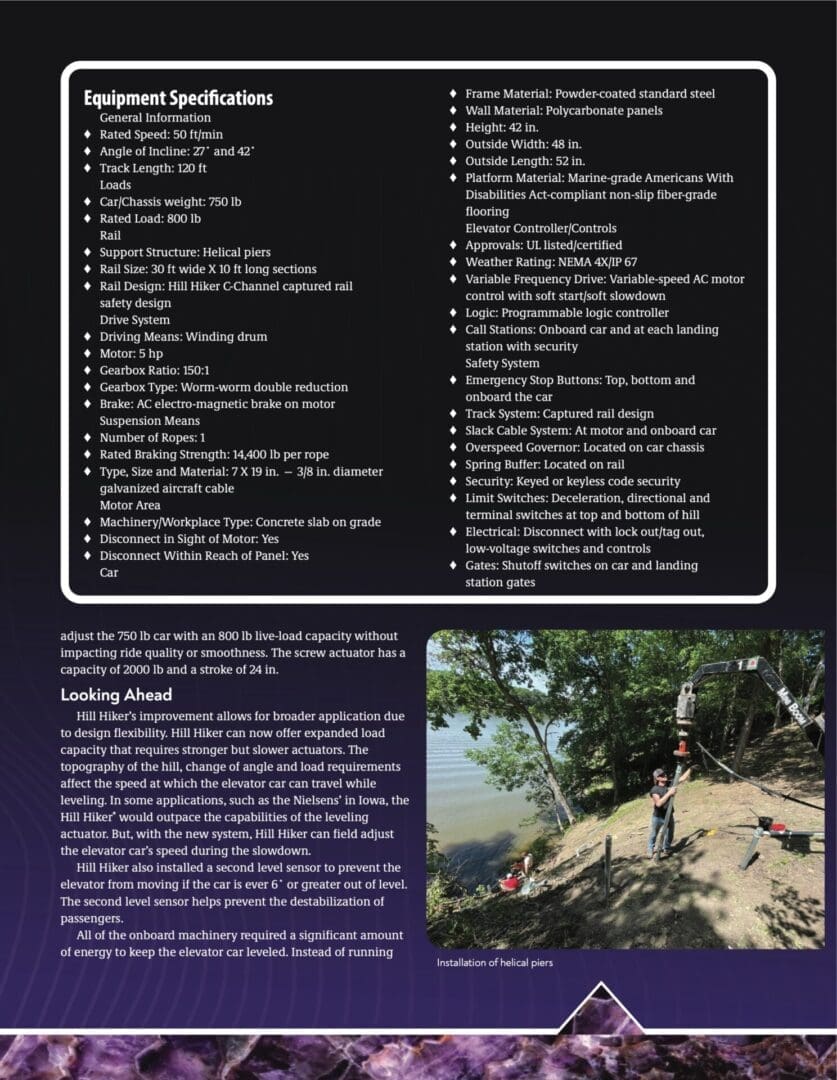

Equipment Specifications

General Information

♦ Rated Speed: 50 ft/min

♦ Angle of Incline: 27˚ and 42˚

♦ Track Length: 120 ft Loads

♦ Car/Chassis weight: 750 lb

♦ Rated Load: 800 lb Rail

♦ Support Structure: Helical piers

♦ Rail Size: 30 ft wide X 10 ft long sections

♦ Rail Design: Hill Hiker C-Channel captured rail safety design

Drive System

♦ Driving Means: Winding drum

♦ Motor: 5 hp

♦ Gearbox Ratio: 150:1

♦ Gearbox Type: Worm-worm double reduction

♦ Brake: AC electro-magnetic brake on motor

Suspension Means

♦ Number of Ropes: 1

♦ Rated Braking Strength: 14,400 lb per rope

♦ Type, Size and Material: 7 X 19 in. — 3/8 in. diameter galvanized aircraft cable

Motor Area

♦ Machinery/Workplace Type: Concrete slab on grade

♦ Disconnect in Sight of Motor: Yes

♦ Disconnect Within Reach of Panel: Yes

Car

♦ Frame Material: Powder-coated standard steel

♦ Wall Material: Polycarbonate panels

♦ Height: 42 in.

♦ Outside Width: 48 in.

♦ Outside Length: 52 in.

♦ Platform Material: Marine-grade Americans With Disabilities Act-compliant non-slip fiber-grade flooring

Elevator Controller/Controls

♦ Approvals: UL listed/certified

♦ Weather Rating: NEMA 4X/IP 67

♦ Variable Frequency Drive: Variable-speed AC motor control with soft start/soft slowdown

♦ Logic: Programmable logic controller

♦ Call Stations: Onboard car and at each landing station with security

Safety System

♦ Emergency Stop Buttons: Top, bottom and onboard the car

♦ Track System: Captured rail design

♦ Slack Cable System: At motor and onboard car

♦ Overspeed Governor: Located on car chassis

♦ Spring Buffer: Located on rail

♦ Security: Keyed or keyless code security

♦ Limit Switches: Deceleration, directional and terminal switches at top and bottom of hill

♦ Electrical: Disconnect with lock out/tag out, low-voltage switches and controls

♦ Gates: Shutoff switches on car and landing station gates

Looking Ahead

Hill Hiker’s improvement allows for broader application due to design flexibility. Hill Hiker can now offer expanded load capacity that requires stronger but slower actuators. The topography of the hill, change of angle and load requirements affect the speed at which the elevator car can travel while leveling. In some applications, such as the Nielsens’ in Iowa, the Hill Hiker® would outpace the capabilities of the leveling actuator. But, with the new system, Hill Hiker can field adjust the elevator car’s speed during the slowdown. Hill Hiker also installed a second level sensor to prevent the elevator from moving if the car is ever 6˚ or greater out of level. The second level sensor helps prevent the destabilization of passengers. All of the onboard machinery required a significant amount of energy to keep the elevator car leveled. Instead of running power to the elevator through a traveling cable (which is not reliable in outdoor settings) Hill Hiker designed a system where all components are energized by a single deep cycle 12-V DC marine battery. We also established a charging station at the top landing station. Charging station pads are connected to a metered trickle charger to prevent overcharging the battery. The elevator car connects to the charging station through custom-mounted conductive flow-through brushes. The brushes allow reliable contact on the charging pads and do not create an electrical hazard to bystanders. Hill Hiker mounted an in-car battery gauge to easily monitor the battery’s health. Hill Hiker has applications all over the world and has developed a high level of adaptability to meet customers’ needs using many different types of foundations, installation methods and unique equipment. Hill Hiker added to its experience and displayed a strong aptitude for innovation to complete the Panora project. The team at Hill Hiker, Hayes Construction and Country Landscapes worked together to overcome the unique challenges the hillside posed and help make the customers’ dream vacation home a reality with a safe and reliable method of transportation from home to shoreline.

Credits

Owners: Jared and Hillary Nielsen

Location: Panora, Iowa

Manufacturer, Contractor and Elevator Designer: Hill Hiker, Inc., Orono, Minnesota

Design/Engineering: VAA Engineering, Plymouth, Minnesota, Aaron Fortunato, PE, and Dustin Foth, technician

Electronic Design/Supplier: ISC Companies, Plymouth, Minnesota, Mike Dahlin

Project Consultant/Manager and Construction Distributors: Country Landscapes, Inc., Ames, Iowa, Nick Brosamle

Homebuilder: Hayes Construction, Panora, Iowa, Rick Hayes

Collaborative Article Authors: Bill MacLachlan, Hill Hiker, Inc., owner and founder; Duncan MacLachlan, project manager; and Harrison Swadley, sales assistant

Source:

MacLachlan, Bill. “Following Nature’s Path.” Elevator World, Jan. 2023, pp. 58-61.